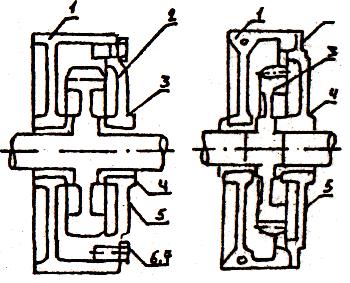

with geared transmission with axial assembly: 1- body; 2-cover; 3- gear-shaft; 4- plain bearing; 5- cover; 6- bolt; 7-washer |

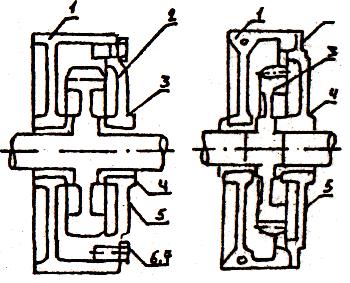

with radial assembly: 1- body; 2- cover; 3- gear-shaft; 4- plain bearing; 5- cover |

with geared transmission with axial assembly: 1- body; 2-cover; 3- gear-shaft; 4- plain bearing; 5- cover; 6- bolt; 7-washer |

with radial assembly: 1- body; 2- cover; 3- gear-shaft; 4- plain bearing; 5- cover |